Soy protein concentrate: an efficient source of protein in animal feeding

2020년 06월 10일

- Feed

- Function

- Nutrition

INTRODUCTION

oybean meal is number one plant-based protein source used for animal feeding all over the world. In total 233.66 million metric tons of the soybean meal has been used for the animal feeding in the year 2017-18. The popularity of the soybean meal is due to its balanced amino acid profile when balanced with most cereal grains and its abundant concentrations of the essential amino acids like Lys, Met and Thr.

Manufacturing of Soybean meal

In spite of the fact that Soybean meal is most common source of quality protein in animal feeding, it also contains anti-nutritional factors like allergen, trypsin inhibitors and undigestible oligosaccharides such as raffinose and stachyose. These decrease the digestibility and nutritional value of soybean meal for animals. In order to reduce the harmful effects of these anti-nutritional factors, soybean meal is toasted during processing. However, due to several reasons the under toasting or over toasting of the soybean meal can be a problem. Under processing of the heat treatment leaves the excessive amounts of anti-nutritional factors in the soybean meal whereas, over toasting destroys the essential amino acids and other nutrients.

To control incoming raw material quality, feed mills have to invest significant capital to test each batch of SBM. Moreover, lack of such quality control programs can lead to deterioration of animal performance and subsequent economic losses.

Is the soybean meal the only efficient source of amino acids in animals? Can we not further minimize the anti-nutritional factors? This question will be discussed in this article further in details.

Soy protein concentrate

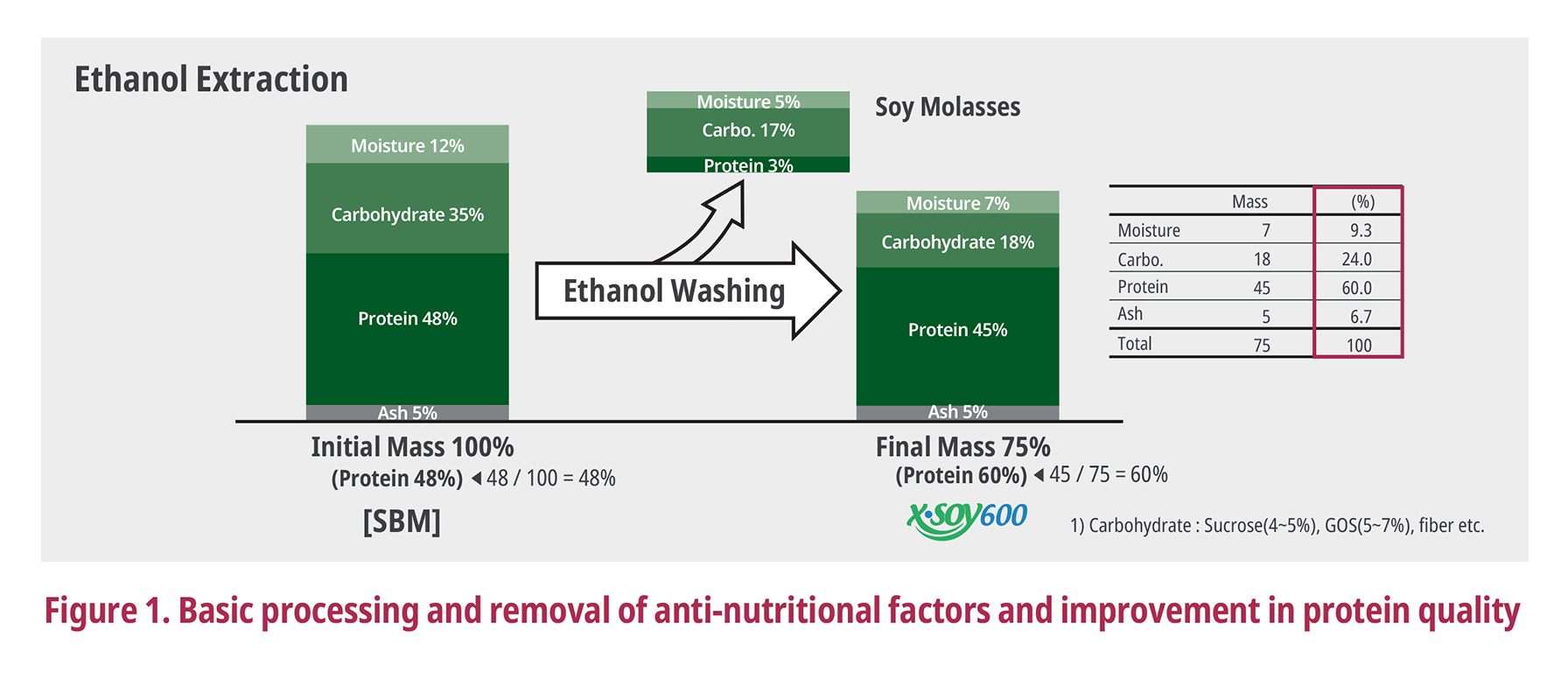

One step beyond the processing of SBM is the further extraction using ethanol under a controlled environment. It is an effective method to not only to minimize the anti-nutritional factors but also improve the protein quality and availability to the animal body (Fig. 1). The product resulting from this process is known as soy protein concentrate (SPC) which is high in nutrient digestibility and contains very low levels of anti-nutritional factors when compared with SBM.

Composition and anti-nutritional factors in SPC

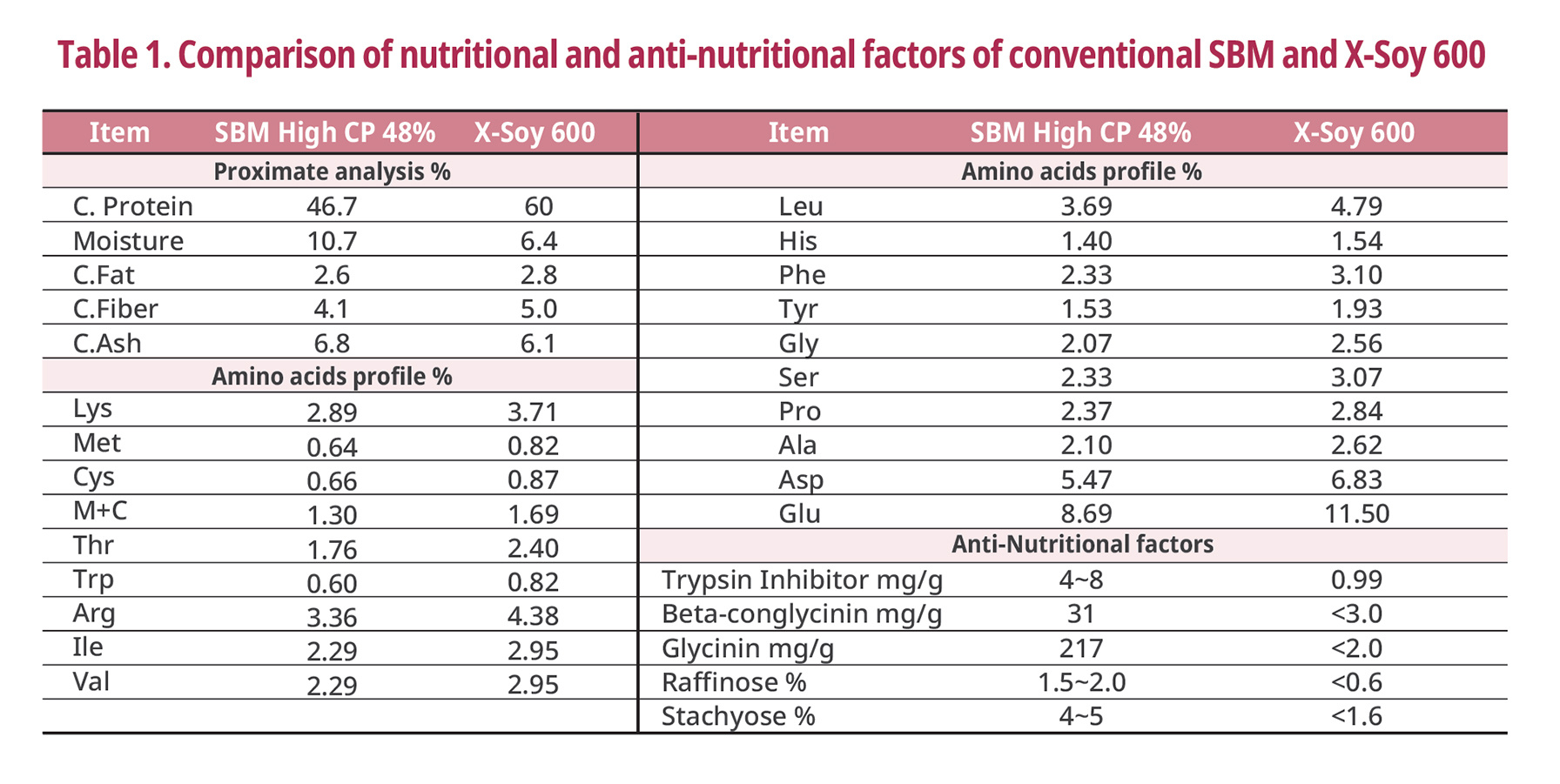

SPC has a balanced quantities of essential amino acids and lower level of anti-nutritional factors as compared to conventional SBM. CJ created a database using different lab analysis for the SBM and the X-Soy 600. The summary of the results are shown in (Table 1).

Efficient protein source in young animals

Young animals have immature digestive tracts which are susceptible to many nutritional challenges during their early development such as weaning period in piglets and 0-7 day starter phase in broilers. Newly hatched chicks when transported from the hatchery are under stress (Transportation, Vaccination). At the same time, an under-developed gastrointestinal (GI) tract can compromise the GI integrity, which may provide an opportunity for pathogenic organisms to grow. Since the GI tract is under-developed, digestive enzymes are not produced in sufficient quantities. At this early stage of growth, birds need a raw material, which can easily be digested provide sufficient amounts of essential nutrients to meet its requirements.

An inefficient digestible protein source at this stage leads to the excessive amounts of undigested protein which serves as a substrate for E. Coli. Which can cause intestinal problems that ultimately leads to diarrhea. A highly efficient source of protein such as SPC could be a reasonable economic alternative for the farmers by reducing expenses for treatment and subsequent mortality.

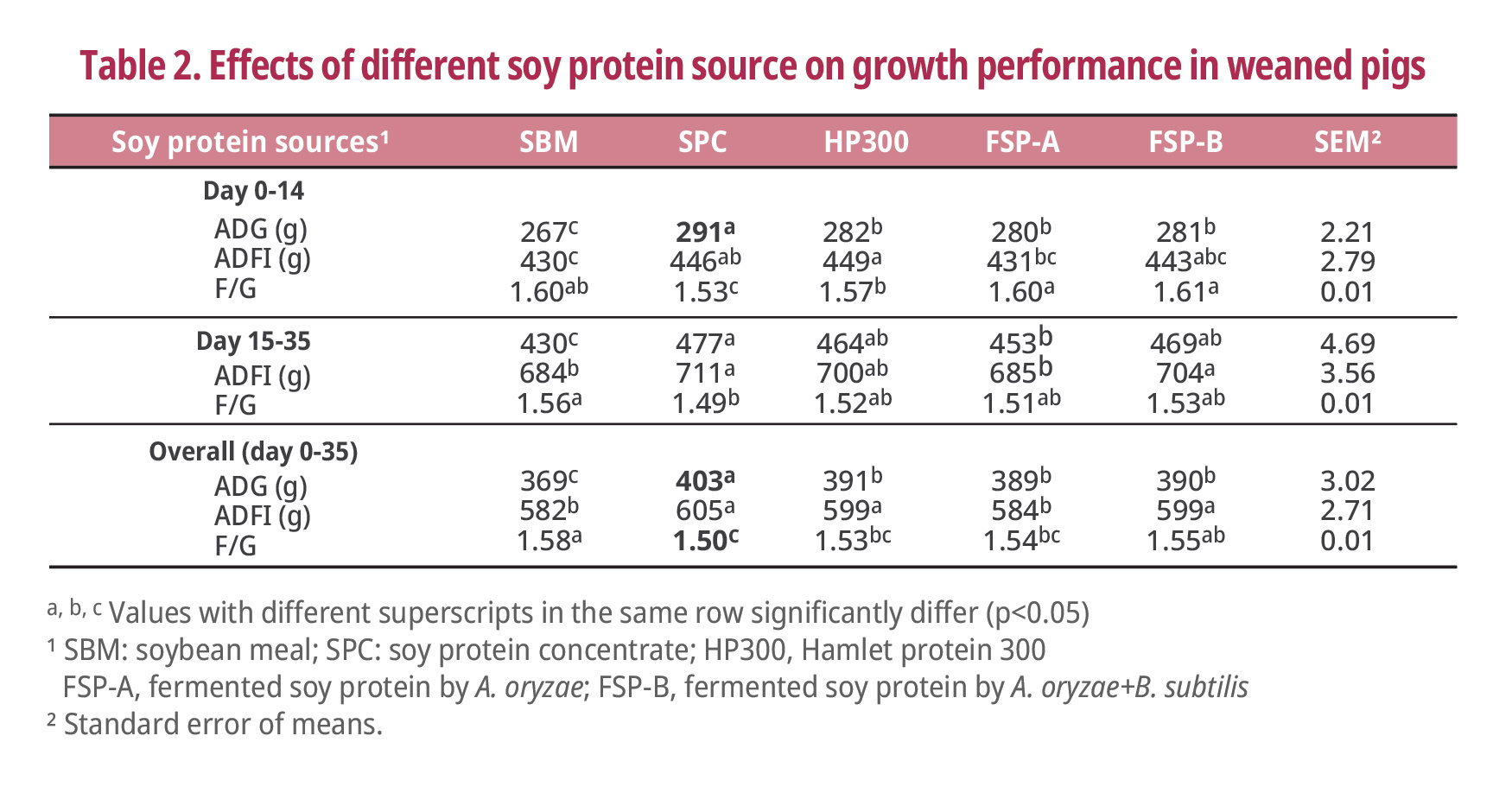

Yang et. al. 2007 tested the efficacy of differently treated sources of soy proteins. They used 280 weaned piglets of 233 days of age, allotted to 5 treatments: conventional SBM, soy protein concentrate (SPC), Hamlet protein (HP300), fungal fermented soy protein (FSP-A; A. oryzae), and fungal+bacterial fermented soy protein (FSP-B; A. oryzae+B. subtilis).

The results of the experiment are shown in Table 2.

Pigs were fed their respective soy protein sources from 0-14d post weaning. Then offered a common commercial diet from 15-35d. The best performance in terms of ADG was achieved in treatment with SPC (291g/d) (P>0.0001) from 0-14d and 403 g/d from 0-35d. The best F/G was also achieved in with SPC: 1.57 and 1.50 from 0-14d and 0-35d respectively compared to other soy protein sources.

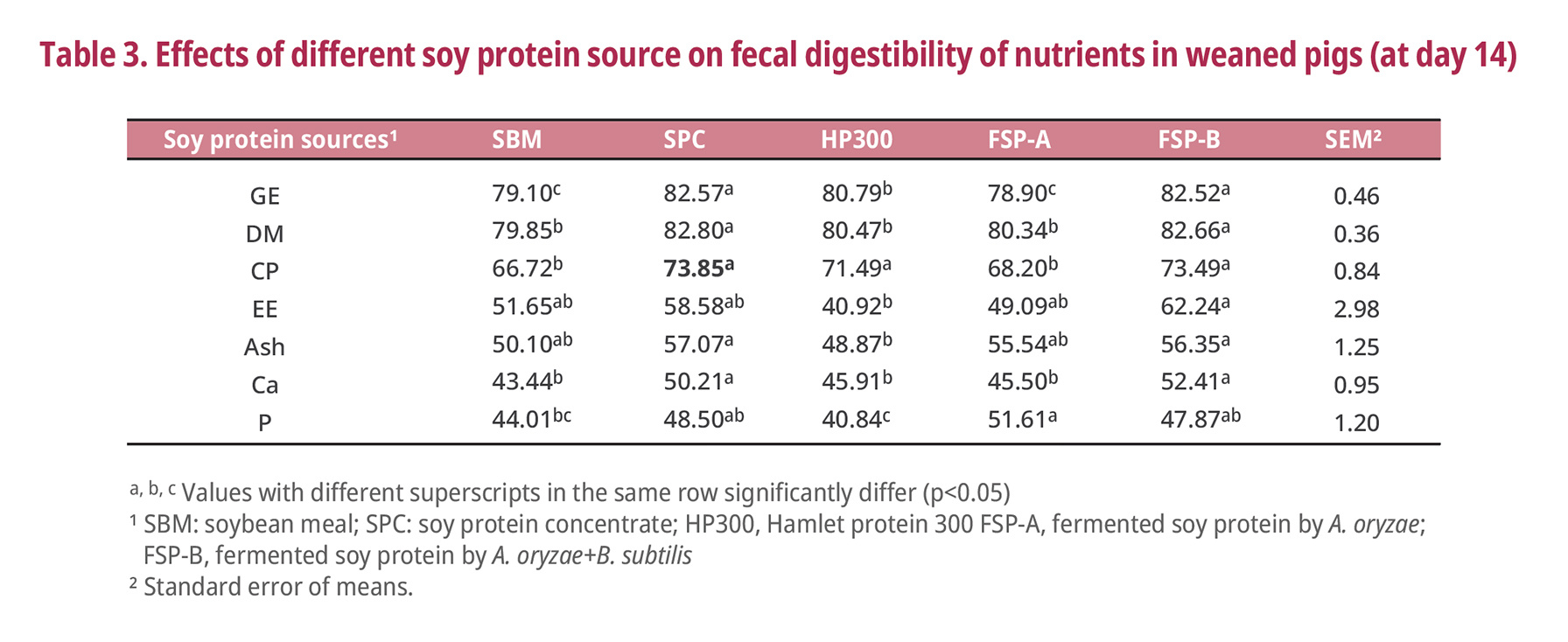

Additionally, fecal nutrient digestibility was measured after 14 days of experimental feeding. Results are presented in Table 3. The digestibility of gross energy, dry matter, CP and calcium were higher (p<0.05) in SPC fed diets compare to SBM or FSP-A. The higher nutrient digestibility found for the SPC group likely explains the resulting increase in weight gain of this treatment group.

CONCLUSION

In conclusion, the performance of young animals can be improved using SPC compared to conventional SBM during their early phase of development. Early development has major impact on an animals overall growth resulting in significant economic, health and performance benefits.

REFERENCES

1. Yang YX, YG Kim, JD Lohakare, JH Yun, JK Lee, MS Kwon, JI Park, JY Choi and BJ Chae. 2007. Comparative Efficacy of Different Soy Protein Sources on Growth Performance, Nutrient Digestibility and Intestinal Morphology in Weaned Pigs. Asian-Aust. J. Anim. Sci. No. 5: 775 - 783